Camera Charging Box for Jeep

Jeep Box

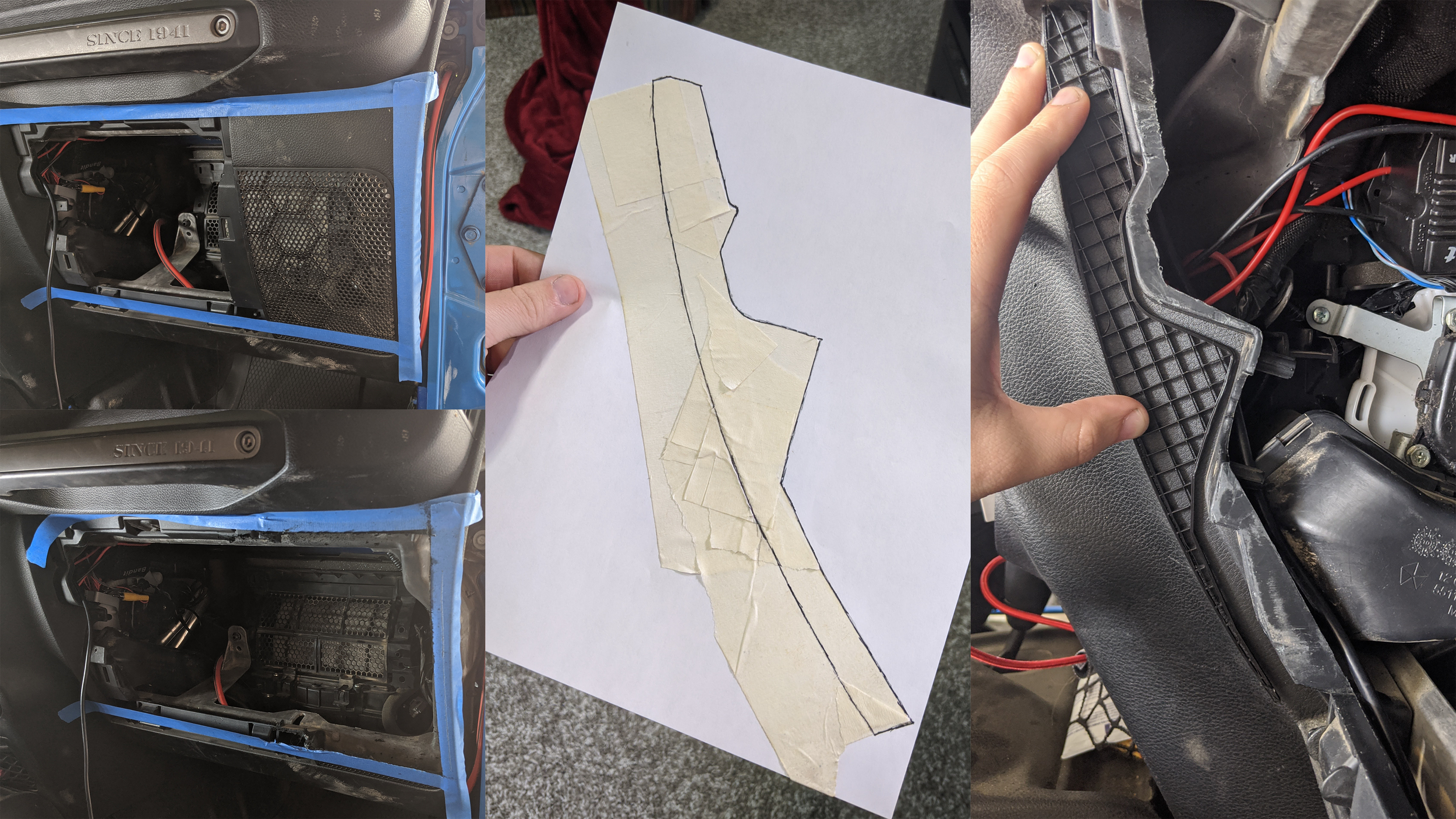

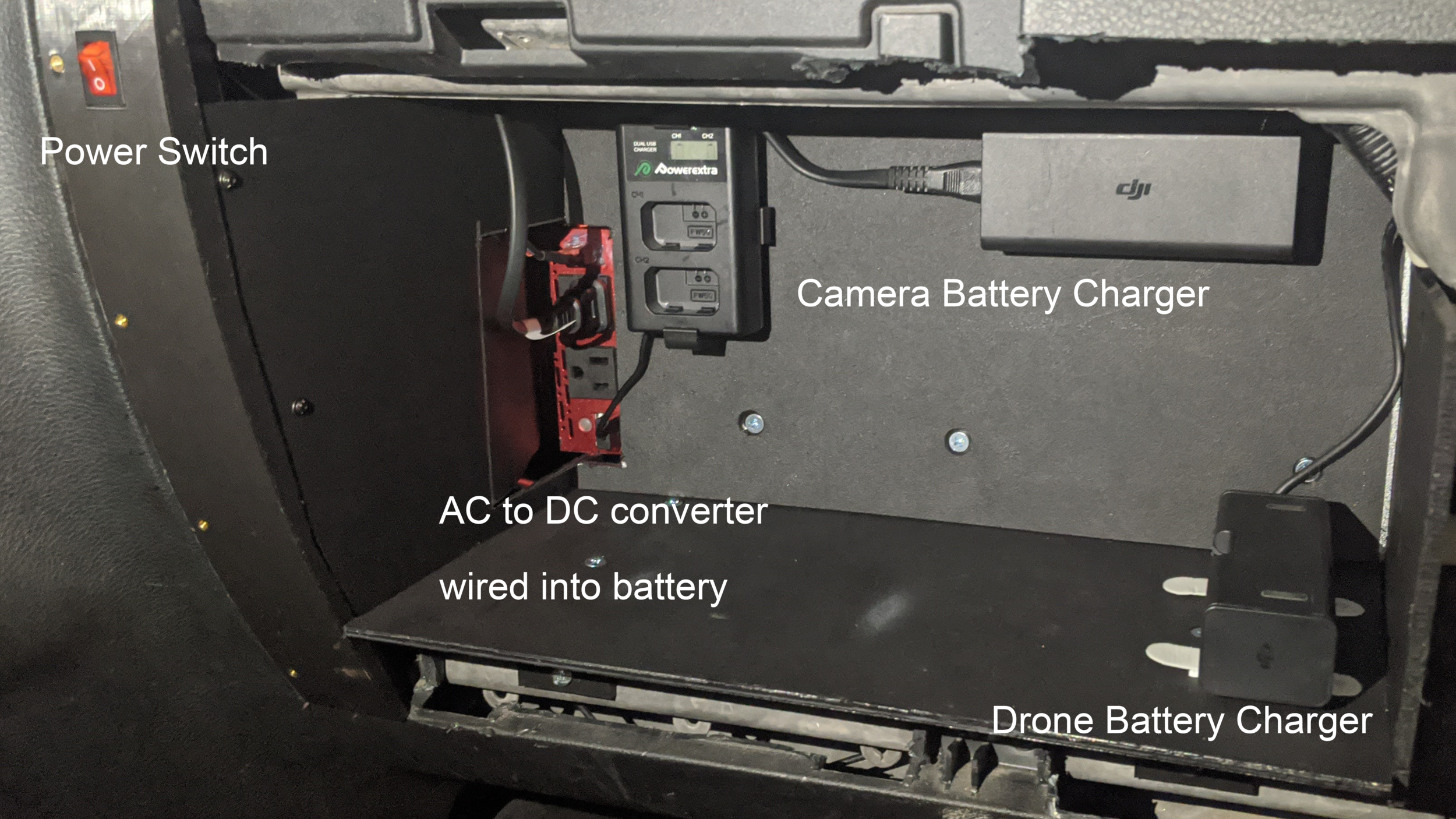

The 2-door Jeep Wrangler is notorious for little storage space to resolve we converted the tiny glove box into a larger storage and charging station. The first version was a bent sheet steel box in the glove box housing that held a CB radio. This box geometry was laser cut out of cardboard in a maker space and then traced out on the sheet steel.

After several long road trips using this box, we had a long list of upgrades we wanted to do. The first and most important upgrade was more space quickly followed by more charging capability. We also decided to use HDPE panels instead of steel as it gave us more flexibility in use and ease of assembly.

Learnings and Skills

Cardboard-aided design and tape can be a very valuable tool when you are working on a project without a base CAD model and are trying to implement 3D printed and normal fabrication seamlessly.

A laser cutter can assist with both prototyping and converting a digital model to reality.

The environmental factor needs to be considered for designing for a vehicle. Such as winter and summer temperature extremes. Additionally, these parts were close to the heating and cooling ducts and needed to be accounted for.

Learned how to make a DIY sheet metal bending and the beginner level Sheet metal bending module in Autodesk Inventor.