Additive Manufacturing Design, Prototyping, and Low-Volume Production

Independent engineering support for teams needing fast iteration, DfAM guidance, or production-ready additive workflows.

Services

-

I help teams evaluate a family of parts and build a complete additive manufacturing pathway—from feasibility through validation and supplier-ready production.

Support includes:DfAM evaluation and part-family feasibility analysis

Material and process selection across polymer and metal AM

Developing mechanical, environmental, and functional test plans

Prototype builds for early performance evaluation

Preparing supplier-ready documentation and production workflows

-

Transforming ideas into manufacturable, print-ready designs optimized for accuracy, strength, surface quality, and cost.

Support includes:

DfAM-driven redesign and feature optimization

Geometry refinement for printability and performance

Reverse engineering and CAD modeling

Topology and generative design for weight or efficiency improvements

-

Fast, functional prototypes that help teams validate design intent before committing to tooling or production.

Support includes:Converting concepts into manufacturable CAD

Selecting the right AM process and material

Incorporating 3D scanning for legacy or modified parts

Producing polymer or metal prototypes

Fit, assembly, and functional validation

-

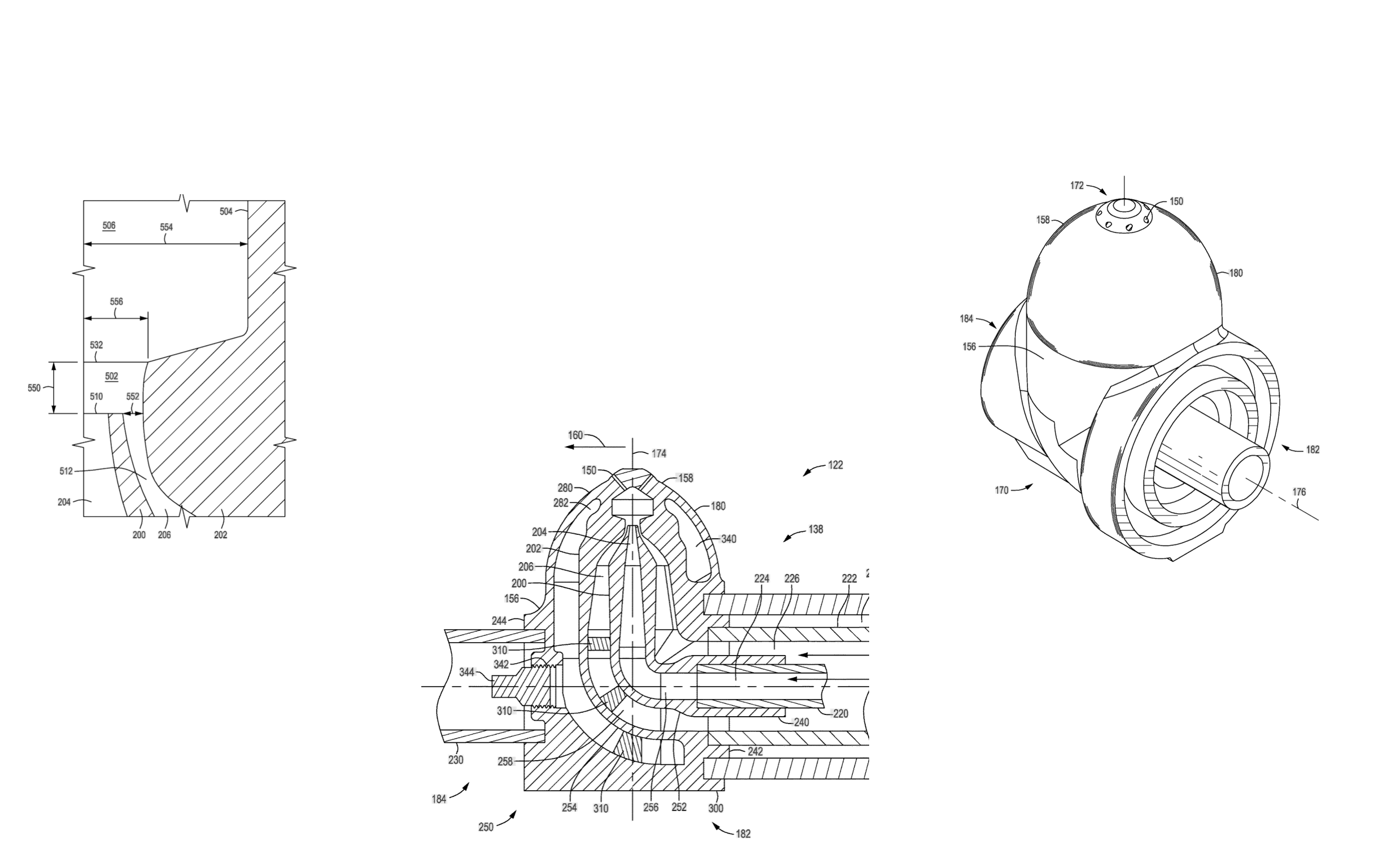

Accurate, high-resolution part capture to support redesign, replacement, or additive adaptation.

Support includes:Precision scanning of complex geometries

Mesh cleanup, alignment, and dimensional analysis

•Scan-to-CAD conversion for modification or reproduction

Fit verification and tolerance assessment

Digitizing legacy or out-of-production components

-

Technical expertise to troubleshoot, optimize, or qualify additive workflows.

Support includes:

Root-cause analysis and print recovery

Orientation, support strategy, and scaling compensation

DOE-driven process tuning

CT-based corrective actions and CAD compensation

Machine, vendor, and workflow evaluation

-

If you need functional polymer components or tooling aids, I can design, print, and deliver small-batch builds:

Assembly tools, fixtures, ergonomic aids

Flexible components (grommets, diaphragms, seals)

Precision polymer parts

Hybrid assemblies combining polymer + metal

-

I help teams new to additive manufacturing ramp up quickly.

Training options include:DfAM best practices

Additive workflow development

Design reviews and print file preparation

Photopolymer/LPBF troubleshooting

Material behavior and qualification basics

Business-case development

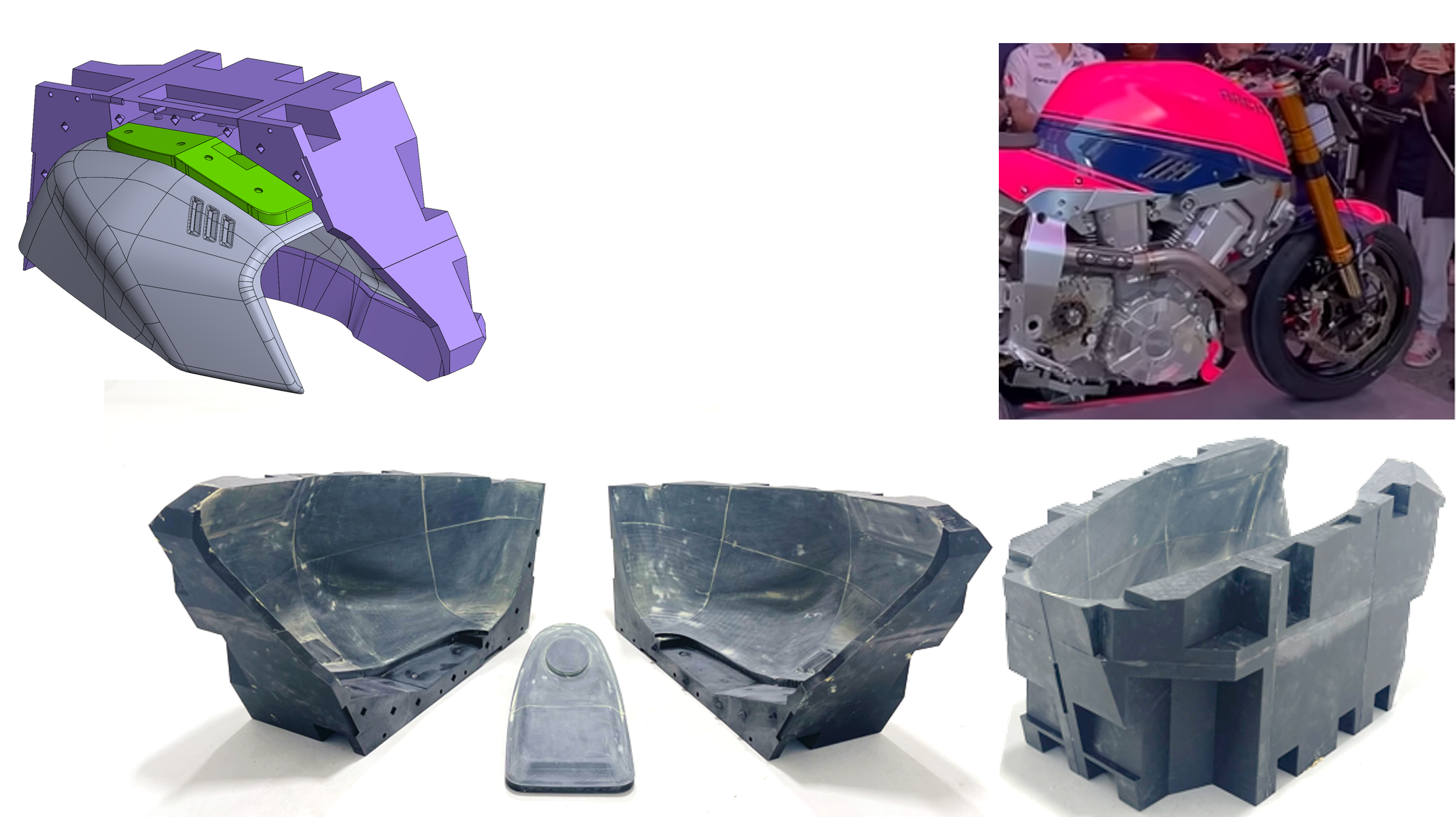

Representative Work

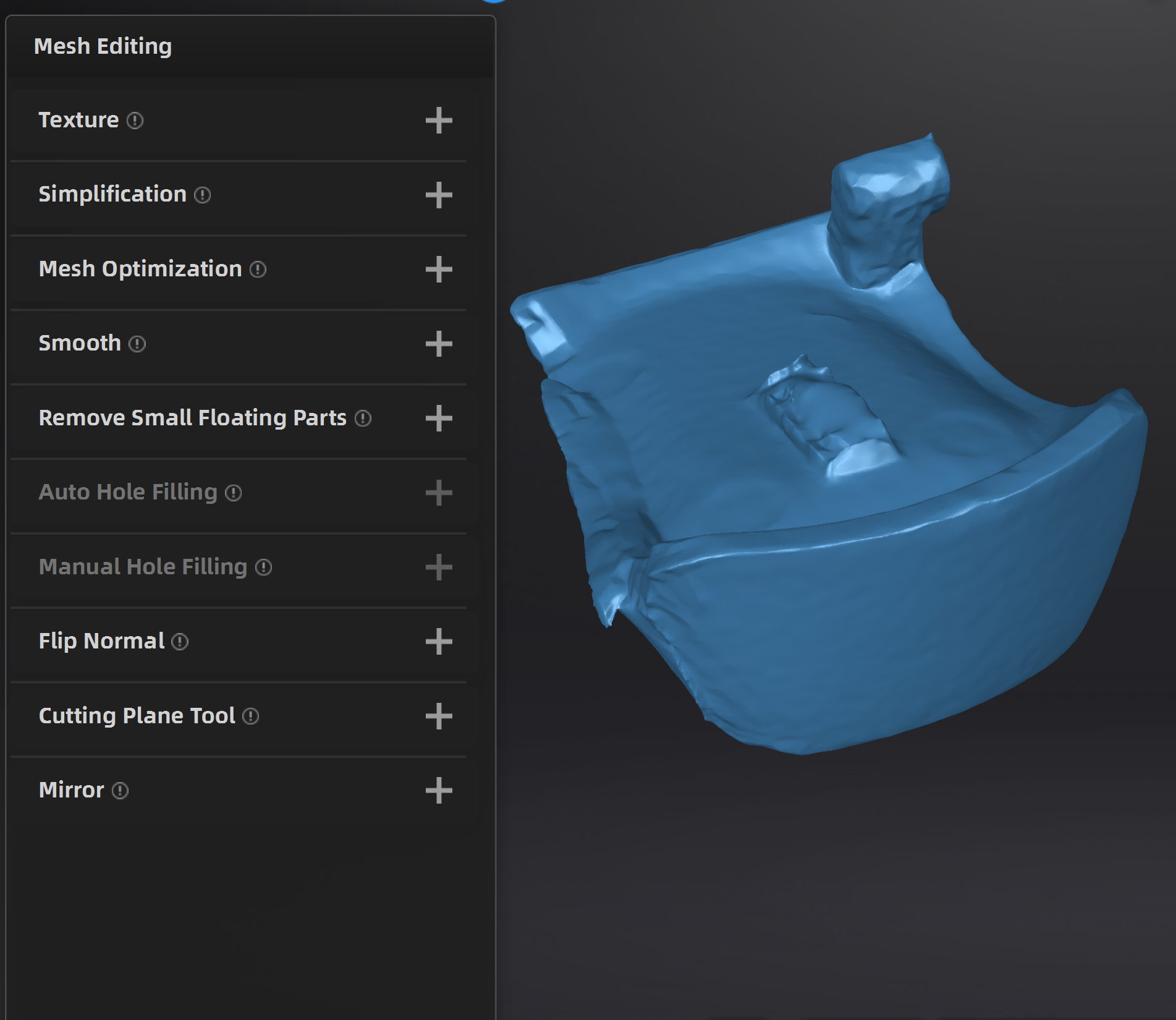

Editing the Mesh

Holes were filled

Optimized and simplified mesh allowing for easy manipulation in Fusion360

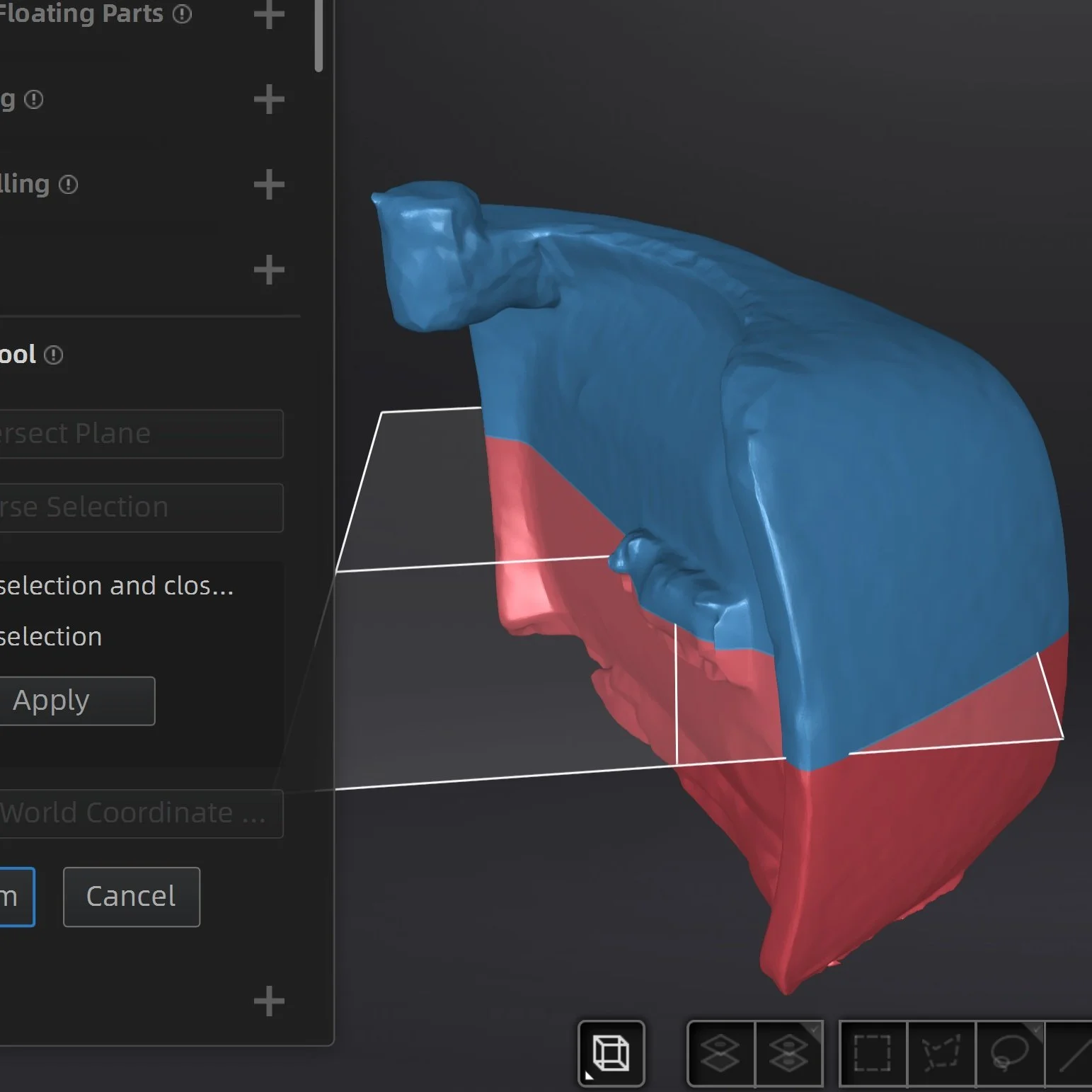

Cutting and Alignment

Cutting the Scan in half for mirroring in Fusion360

This also aligns the cut plan with the global coordinate system

Adding features

Converting .stl into body

Orreinting in Fusion360

Mirroring surfaces and adding accurate interfacing features