Hand layup Carbon Fiber longboard

This 2.5lb carbon fiber long board deck has been put through its paces as it was my daily transportation around my college campus. Extremely ridge and light it was everything you would expect out of a carbon fiber long board.

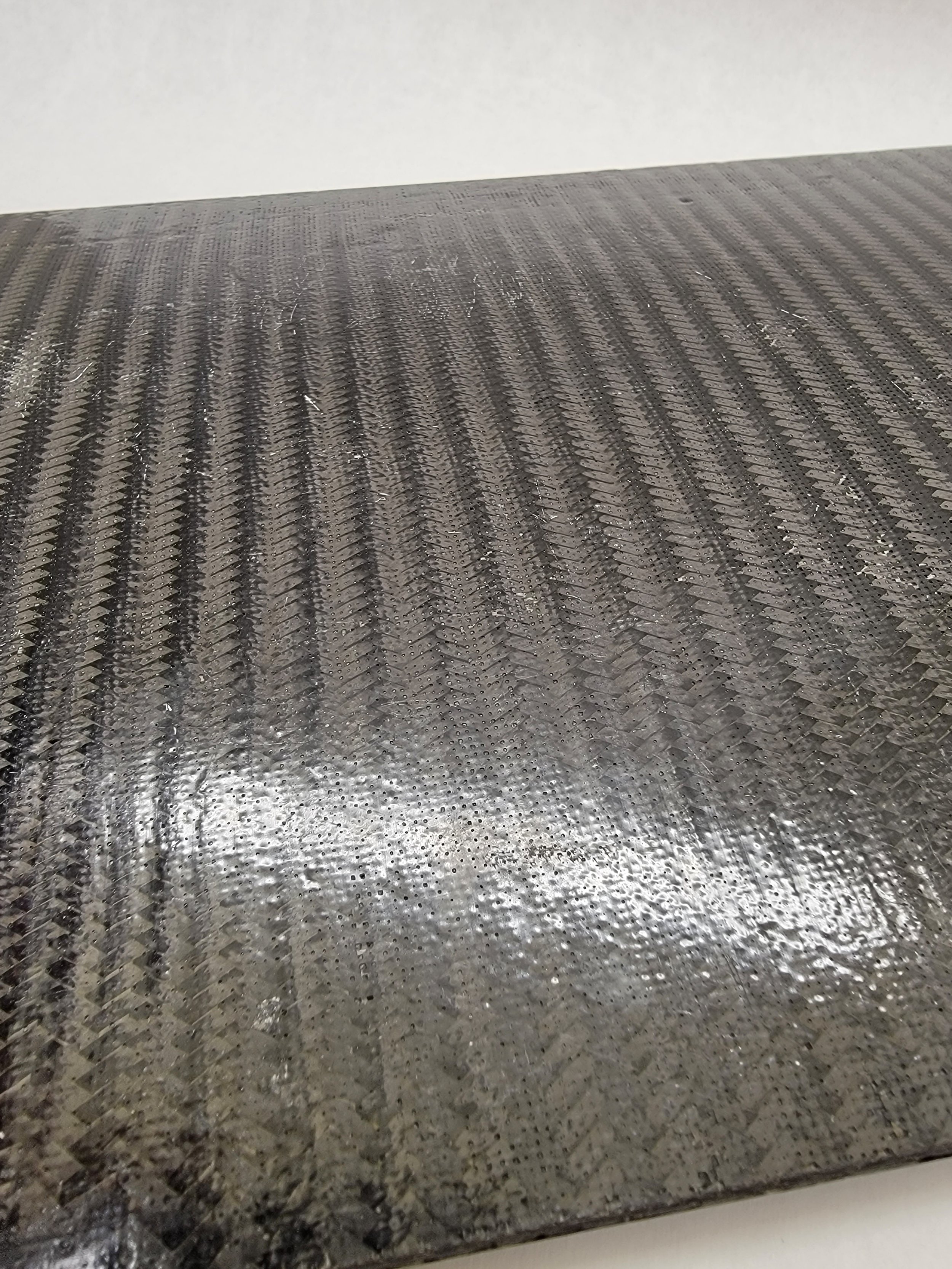

We used a vacuum infusion system to create the board final lay up. The boards compound curve was create by vacuumed forming against a 3D printed mold. The inner structure was balsa wood was preformed while the carbon fiber cloth was being cut. We used a uni-directional and a 45X45 weave for extra strength.

The DIY carbon fiber deck compared to a Landyachtz bamboo and fiberglass board

Carbon fiber being infused with epoxy resin

The laminate consisted of 1 ply Tri-axil (90+45-45) of carbon , 2 ply of Uni-directional (0) of carbon and a 3/8in balsa core. Then mirrored it on the other side of the balsa.

The mold was create using HDPE sheet formed to the 3D printed concave geometry

Learnings and Skills

Hands on experience with infusion layups

Cutting carbon fiber cloth and mixing room temperature cure epoxy resin system